Ceraboard 100/115

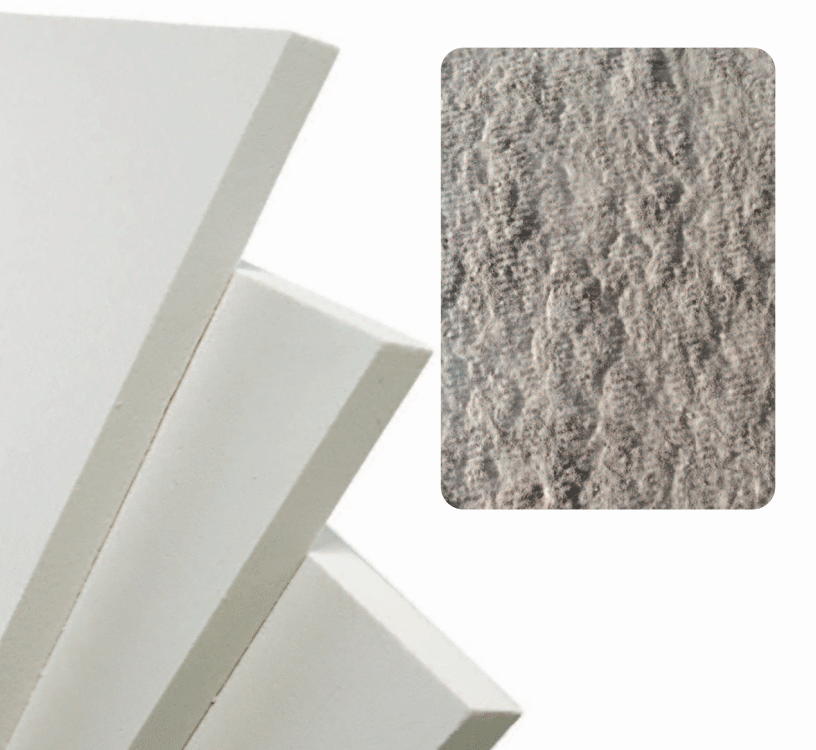

Ceraboard 100, Ceraboard 115 are refractory fibre boards supplied in panels of standard thicknesses made from a slurry of refractory fibres and binders which have a low organic content. The combination of different refractory fibres, inorganic and organic binders in different proportions allows types of boards to be made suitable for different use temperatures. In some types of heating equipment, the emission of fumes, which can occur when binders burn out of the board, can be easily eliminated. Classification temperature of Ceraboard 100 : 1260°C; Ceraboard 115 : 1400°C.

-

ceraboard 100 ceraboard 115 Classification temperaturę °C 1260 1400 Properties Measured at Ambient Conditions (23°C/50 % RH) Colour white/ tan white/ tan Density Kg/m3 310 310 Modulus of rupture MPa 1.0 0,9 Compressive stress at 10% relative deformation MPa 0,35 0,3 High Temperature Performance Loss of ignition after 2 hours heating at 800°C % 5,5 3,5 Permanent linear shrinkage (ASTM C-356) after 24 hours isothermal heating at classification temperature: % 3 3,7 Thermal conductivity (ATM-201) at mean temperature of 300°C (W/m.K) 0,07 0,07 400°C (W/m.K) 0,08 0,08 600°C (W/m.K) 0,11 0,11 800°C (W/m.K) 0,15 0,15 1000°C (W/m.K) 0,2 0,2

-

Standard Dimensions Ceraboard 100 Ceraboard 115 Board per Board per carton pallet carton pallet 1200 x 1000 x 6 – 160 – 160 1200 x 1000 x 7.5 – 120 – – 1200 x 1000 x 10 – 90 – 90 1200 x 1000 x 13 – 72 – – 1200 x 1000 x 15 – 60 – 60 1200 x 1000 x 20 – 48 – 48 1200 x 1000 x 25 – 36 – 36 1200 x 1000 x 40 – 24 – 24 1200 x 1000 x 50 – 18 – 18