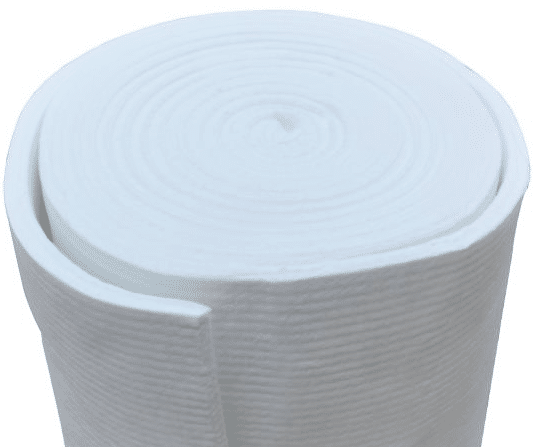

Ceramic Blanket

Ceramic fibres are made from fused oxides of silicon and aluminium through a spinning process. White twisted aluminosilicate fibres with high temperature resistance, low thermal conductivity and good chemical resistance are obtained. Ceramic Blanket consist of aluminosilicate fibres mechanically bonded without additional binding agents. They have excellent resistance to sudden temperature fluctuations. The thermal resistance of ceramic Blanket is, depending on the type: 1260°C, 1400°C. The products find application in various industries as thermal insulation in the construction of ovens, dryers, and fireplaces. Can also be used to insulate boilers, pipelines, and cables as a classic insulation material. Ceramic Blanket serve as an ideal material for the production of modules. Features: o resistance to continuous load up to 1260ºC, 1400ºC; o good insulating properties; o high mechanical stability; o low annealing losses; o high chemical and thermal stability; o low specific gravity and elasticity; o resistance to water, oils, fats, liquid metals, and most acids; o superior electrical insulating properties; o superior acoustic properties; o easy to process; o wide range of formats, uniform density, dimensional stability;

-

Physical properties Classification temperature, ° C 1260 °C 1430 °C Specific gravity, density 96, 128 kg/m³ 96, 128 kg/m³ Melting point 1780 °C 1800 °C Shrinkage after 24 h (at temperature) 3,5 % (1260 °C) 1,8 % (1300 °C) Chemical analysis Al2O3

min. 46 % DIN EN 955-2 SiO2+ Al2O3 min. 97 % Geometric mean fibre length 68 μm 95 μm Thermal conductivity λ at a density of 128 kg/m3 400 °C 0,09 W/mk 600 °C 0,14 W/mk 800 °C 0,20 W/mk 1000 °C 0,27 W/mk 1200 °C 0,34 W/mk

-

Roll width variants 610mm Mat thickness variants 6, 13, 19, 25, 38, 50 mm